Polymers are the favored material for 3D printing for some reasons, including their adaptability and ease. They don’t function admirably for electronic circuits, however. To get around this restriction, the Berkeley scientists printed their circuit plan in a mix of plastic and wax remaining in for the conductive parts. At the point when the wax was uprooted, it exited empty tubes which could then be loaded with conductive metal, and there you have your circuit.

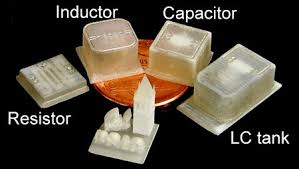

The plans incorporate an electrical resistor, inductor, capacitor and a coordinated inductor-capacitor framework. To demonstrate how such parts could be utilized, a brilliant top was planned and printed. The top contains a little store that catches an example of the fluid when rot. This opens it to a capacitor and inductor to frame a full circuit that can screen the electrical properties of the milk. As the milk begins to go terrible, microscopic organisms duplicate and the change can be recognized by the brilliant top. A radio recurrence test was utilized as a part of this trial to transfer the data to analysts.

The shrewd top cover in this analysis had the capacity to viably gage the rate of bacterial development in the milk, which is only one case of how this 3D printing innovation could be utilized. This bodes well for straightforward hardware with a modest bunch of parts, and shoppers may have the capacity to print such circuits not long from now. This doesn’t mean you’ll be printing a cell phone at any point in the near future, however. The coordinated circuits in advanced hardware are awfully confused for 3D printing, at any rate at this time.